Why Good Wiring and Labeling Matter More Than You Think

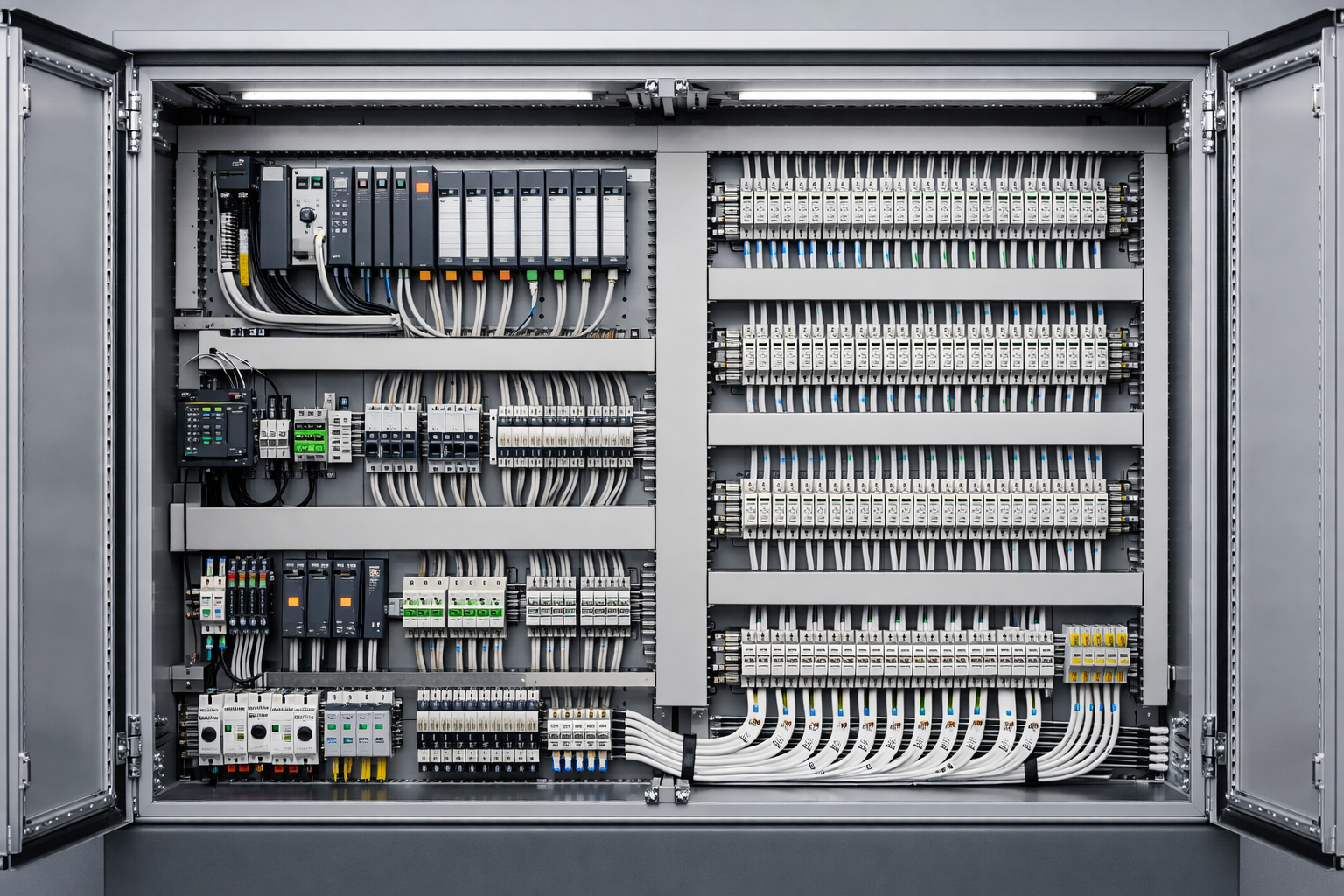

Most people never see the inside of a control panel. If everything is working, there’s no reason to. But the moment something goes wrong, what’s inside that enclosure suddenly matters a lot.

Good wiring and clear labeling aren’t about making a panel look pretty. They’re about saving time, saving money, and keeping people safe, especially years down the road when the original installer is long gone.

Clean layout saves real time

When wiring is routed cleanly, bundled properly, and landed where it makes sense, troubleshooting becomes faster and less stressful. A technician can follow a circuit visually instead of guessing, tugging on wires, or pulling prints apart trying to decode a mess.

That time adds up. A clean panel can turn a two-hour service call into a twenty-minute fix. That’s less downtime for the customer and lower labor costs overall.

Labels prevent mistakes

Clear, consistent wire labels and device tags remove guesswork. When a wire is labeled correctly, there’s no confusion about what it feeds or where it goes. That matters when you’re working live, under pressure, or in a tight shutdown window.

Poor or missing labels increase the risk of disconnecting the wrong circuit, energizing the wrong device, or damaging equipment that wasn’t part of the problem. In the worst cases, it can put people in danger.

Future work becomes easier and cheaper

Panels rarely stay frozen in time. Systems get expanded, upgraded, or repurposed. When wiring is neat and labeling is accurate, adding a new device or modifying an existing circuit is straightforward.

When it’s not? Every change becomes slower, riskier, and more expensive. What should be a simple addition turns into hours of tracing wires and verifying everything twice just to be safe.

It reflects how the job was done

A clean, well-labeled panel usually tells you something important: the person who built it cared about the next person who would work on it. That mindset carries through the entire project — from design decisions to component selection to documentation.

Messy wiring often points to rushed work, shortcuts, or lack of planning. You may not notice it on day one, but it shows up later when something fails.

It’s about safety, not looks

At the end of the day, good wiring practices reduce risk. Clear routing lowers the chance of damaged insulation. Proper labeling reduces human error. Logical layout helps technicians work confidently instead of cautiously guessing.

Those details matter most when conditions aren’t perfectm, during emergency calls, night work, or unexpected failures.

Good wiring and labeling aren’t extras. They’re part of doing the job right, not just for today, but for everyone who has to touch that panel years from now.

|